|

||||||

|

|

||||||

|

|

|

Laminated glass manufacturing process

|

|

|

Cross cutting - Forming - Edge polishing

|

|

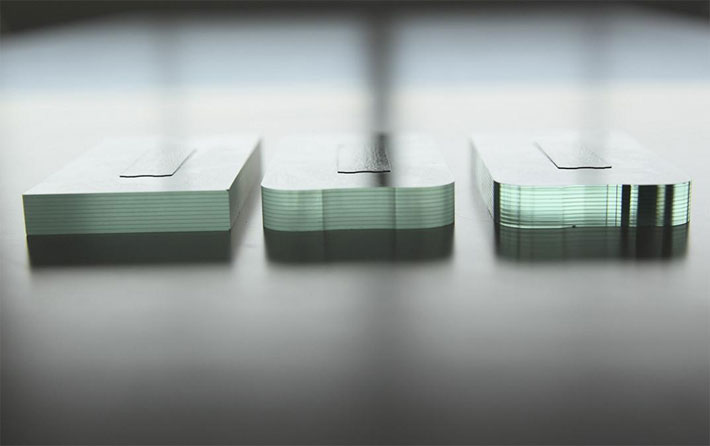

Laminating

|

|

○ Laminated (stacked) glass for all the following process

○ Protect scratch or diat, compared one by one process ○ Stable quality Resin glue or PP film |

|

Cross cutting

|

|

○ Auto X-Y cutting by NC (Max. 550 x 550)

○ Cutting laminated glass block by block (Ma15mm) ensures fine edge and accuracy |

|

Forming

|

|

○ Recessed edge, slot and round hole

○ Auto processing with Auto Tool Changer and high speed spindle ○ Programmed with CAD/CAM data |

|

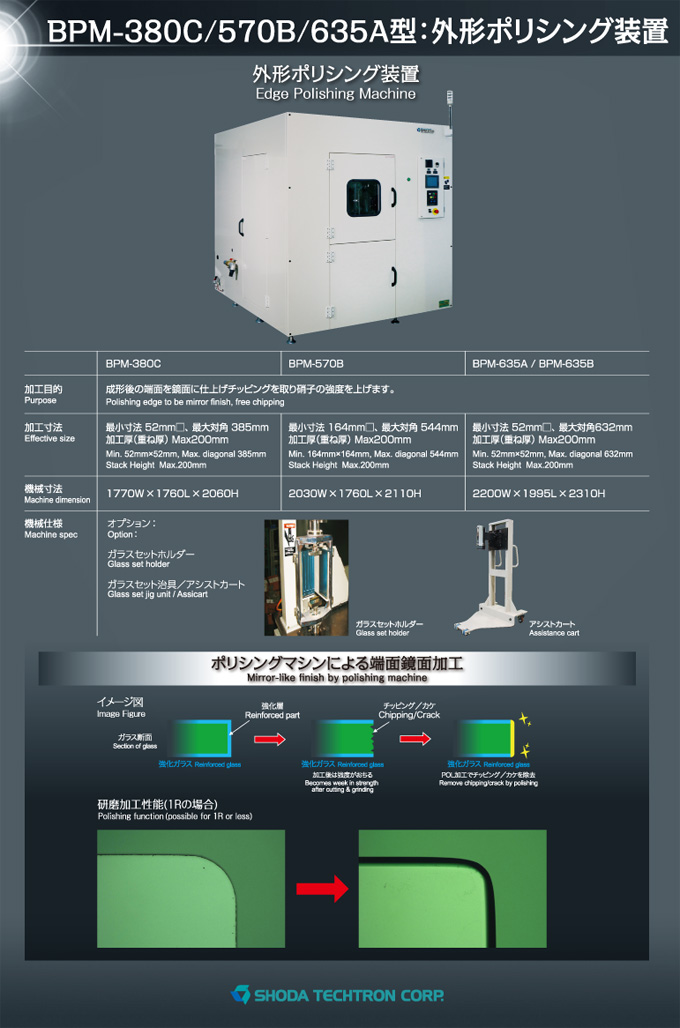

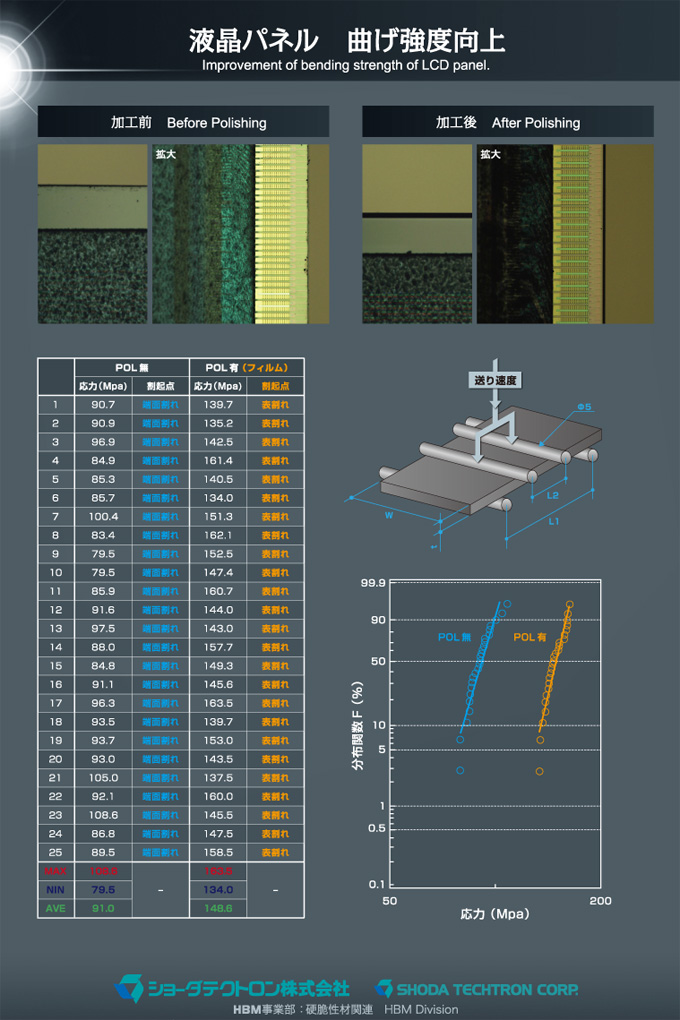

Edge polishing

|

|

○ Brush polishing to be mirror finish

○ Max. 200mm glass in one water |

|

Peeling

|

|

○ Peeled with hot water |

|

|

| CCM-550A |  |

|

| Cross Cutting Machine | ||

| Purpose | X-Y cutting machine for large glass | |

| Effective size | Max : 550Wx550Lx15t (mm) | |

| Machine dimension | 1860Wx2210Lx1970H | |

| Machine spec | Option : CCD camera (for reference mark) |

| GMF-550A |  |

|

| Forming Machine | ||

| Purpose | It routes outer shape | |

| Effective size | Max : 550Wx550Lx15t (mm) | |

| Machine dimension | 1460Wx2053Lx2263H | |

| Machine spec | Single spindle , with ATC, Option : CCD camera (for reference mark) |

| UHD-300A型 |  |

|

| Ultrasonic Coring Machine | ||

| Purpose | Coring by Ultrasonic | |

| Effective size | Max : 300Wx150Lx15t (mm) | |

| Machine dimension | 1300Wx1600Lx2000H |

|

|

|

|

|